Atlantic Fasteners Blog: Understanding Cryo Treating

What is Cryo Treating?

Cryo-treating is a slow process of taking materials down to -300° F, typically in liquid nitrogen, and gradually bringing them back to room temperature over several days.

The end result is a considerably longer life with less internal stress, more flexibility, and higher tensile strength for everything from end mills, reamers, and broaches, to drill bits, pump parts, and much more. Depending on the material, cutting tools typically last 2 – 5 times longer – some, much longer.

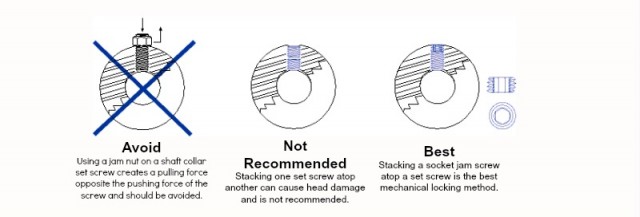

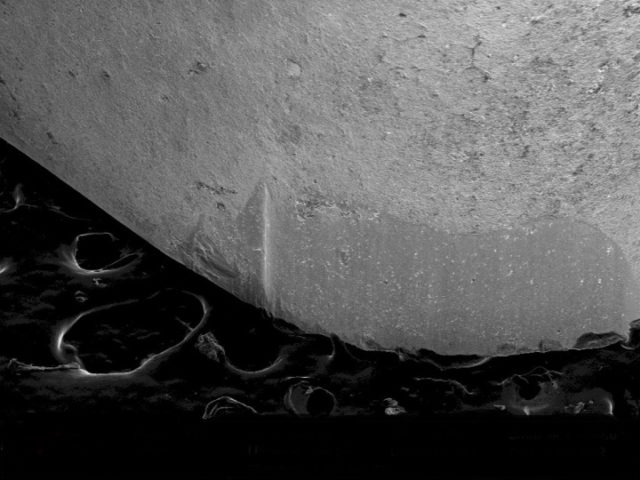

Non-treated carbide cutter bit, magnified 69x

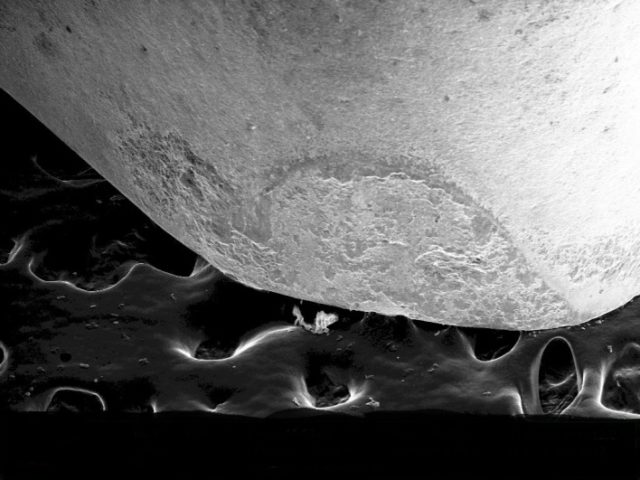

Cryo-treated carbide cutter bit, magnified 69x

Notice the smooth cutting edge of the treated bit. Both bits came from the same mfg batch and were used to bore cylinders in cast iron engine blocks.

The non-treated bit was leaving a rough finish, not boring to size, and squealing by the 3rd cylinder. The treated bit was still boring a smooth finish, to size, with no squealing, on the 34th cylinder – 11 times more life!

(Photos, drawing, and case study courtesy of Carter Cryogenics)

How Cryo Treating Works

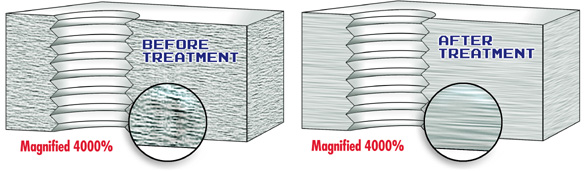

At room temperature, before parts are cooled, their molecules are a rapidly-moving tangled mass. As temps drop below 300° F, the molecules slow down, almost stopping. Then, as the parts are gradually warmed to room temp, the molecules realign themselves in an orderly, evenly distributed pattern. This relieves stress and gives parts superior strength and wear resistance.

The even distribution of molecules through cryo-treating creates strength

The cryo process penetrates parts to their core. It’s not just a surface treatment that wears off after repeated use or resharpening. One treatment is permanent.

Case Study Briefs

- From a paper converter in Agawam, Massachusetts: M-2 Lenox knives were lasting 70 production hours before treatment; 240 production hours after cryo-treating.

- From a paper mill in Glens Falls, New York: a ductile iron pumper impeller was lasting 6-7 months without processing; 14 months with processing.

- From a chemical plant in Springfield, Massachusetts: the processing of high-speed steel twist drills increased their life by 300%.

- From a chemical plant in Waterford, New York: O-1 granulator blades that previously lasted 100 runs, were lasting 120 runs with processing.

- From a metal fabricator in Holyoke, Massachusetts: M-2 tool steel punch dies that needed resharpening after 12,000 hits were like new after 24,000 hits, with processing.