Comparison of Common Drill Point Styles

Tech Tip: Comparison of Common Drill Point Styles

"Maintenance people and buyers alike find drill point styles confusing,” says Atlantic’s Customer Service Manager, Tony Orvis, who’s been in the fastener business for 26 years.

“One is good for soft material, another for hard. One typically requires center punching, the other doesn’t,” he continues.

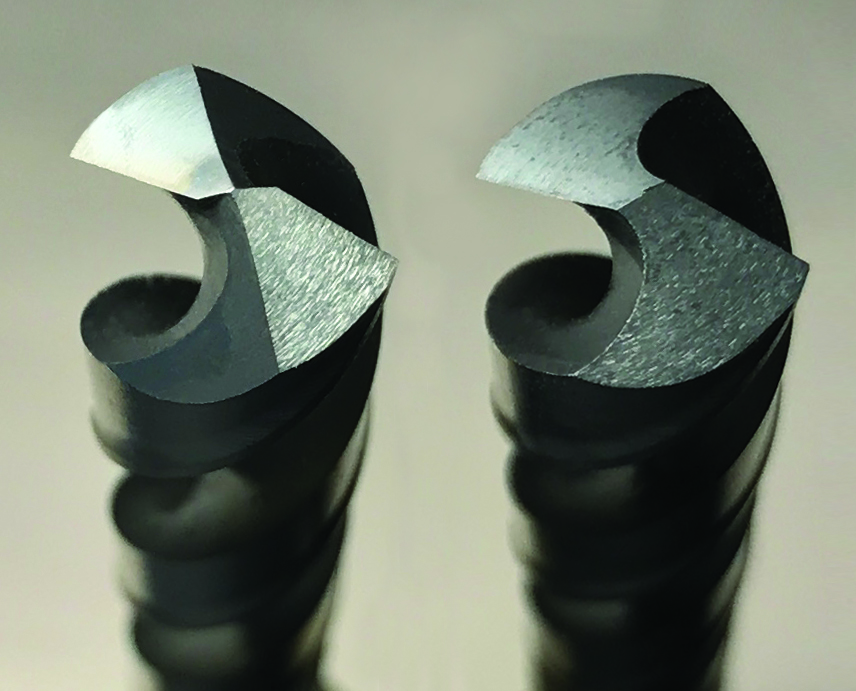

So Orvis says he approached Atlantic’s technical and marketing departments to create a simple comparison piece on the two most popular drill point styles, 135° split point and 118°. His chief request was for a sharp picture of each tip, so the differences are readily apparent.

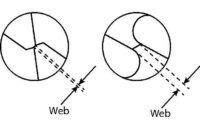

The two most common drill point styles are 135° split point and 118°. As you can see from the picture, the 135° has four cutting edges while the 118° has two.

135°split point drill bit (L) and 118° point

Which is best for your applications?

135° split point

- Drills faster – 4 cutting edges

- Works well on curved shapes and hardened materials such as high alloy steels and stainless steel

- Suitable for hand drilling, drill presses, and CNC’s

- Creates smaller chips that eject quickly, minimizing the risk of chips clogging holes and bits breaking

- Self-centering so no center punch required

- Requires less force due to thinner web, so there’s less heat

and work hardening.

and work hardening. - Bits last longer

- More difficult to sharpen

118° split point

- 2 cutting edges

- For general use in stationary drills, such as drill presses

- Works well in soft materials like wood, cast iron, copper, brass, and mild steel

- Not self-centering – use of center punch recommended, especially on curved or hard surfaces

- Dulls much faster, but easier to sharpen